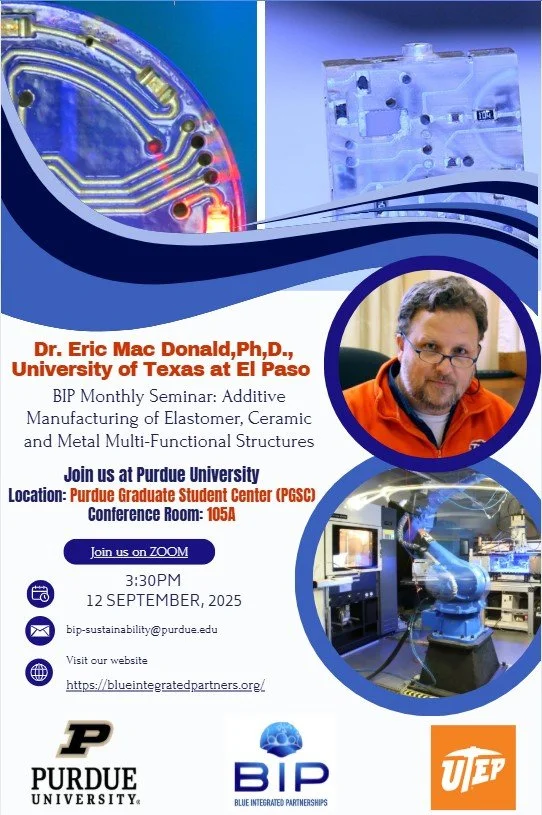

Additive Manufacturing of Elastomer, Ceramic and Metal

Multi-functional Structures

Eric MacDonald, Ph.D., P.E.,

Murchison Chair and Professor, Aerospace and Mechanical Engineering

Associate Dean of Research and Graduate Studies, College of Engineering

The University of Texas at El Paso

Joint Faculty Appointment, Oak Ridge National Laboratory

Abstract

3D printing has been historically relegated to fabricating conceptual models and prototypes; however, increasingly, research is now focusing on fabricating functional end-use products. As patents for 3D printing expire, new low-cost desktop systems are being adopted more widely and this trend is leading to a diversity of new products, processes and available materials. However, currently the technology is generally confined to fabricating single material static structures. For additively manufactured products to be economically meaningful, additional functionalities are required to be incorporated in terms of electronic, electromechanical, electromagnetic, thermodynamic, chemical and optical content. By interrupting the 3D printing and employing complementary manufacturing processes, additional functional content can be included in mass-customized structures. This presentation will review work in multi-process 3D printing for creating structures with consumer-anatomy-specific wearable electronics, electromechanical actuation, electromagnetics, energy storage, propulsion, embedded sensors in soft tooling – in polymers, elastomers, metal and ceramic material systems.

Eric MacDonald's Biography

Eric MacDonald, Ph.D. is a professor of aerospace and mechanical engineering and Murchison Chair at the University of Texas at El Paso and serves as the Associate Dean of Research and Graduate Studies for the College of Engineering. Dr. MacDonald received his doctoral degree (2002) in Electrical and Computer Engineering from the University of Texas at Austin. He worked in industry for 12 years at IBM and Motorola and subsequently co-founded a start-up specializing in CAD software and the startup was acquired by a firm in Silicon Valley. Dr. MacDonald held faculty fellowships at NASA’s Jet Propulsion Laboratory, US Navy Research and was awarded a US State Department Fulbright Fellowship in South America. His research interests include 3D printed multi-functional applications and process monitoring in additive manufacturing with instrumentation and computer vision for improved quality and yield. As a co-founding editor of the Elsevier journal Additive Manufacturing, MacDonald has helped direct the academic journal to have highest impact factor among all manufacturing journals worldwide. He has recently been involved in the commissioning of a second partner journal, Additive Manufacturing Letters, upon which he serves as the Editor-in-Chief. Recent projects include 3D printing of structures such as nano satellites with structurally-embedded electronics - one of which was launched into Low Earth Orbit in 2013 and a replica of which was on display at the London Museum of Science. He has over 100 peer-reviewed publications, dozens of patents, one of which was licensed by Sony and Toshiba from IBM. He is a member of ASME, ASEE, senior member of IEEE and a registered Professional Engineer in the USA state of Texas.

Join Zoom Meeting

https://purdue-edu.zoom.us/j/7992551685?pwd=eTVMQzc0RW04U2JyL1l5c0kzR1NnQT09

Meeting ID: 799 255 1685

Passcode: 4YX6kK

Join by SIP

7992551685@zoomcrc.com

Join by H.323

162.255.37.11 (US West)

162.255.36.11 (US East)

Meeting ID: 799 255 1685

Passcode: 490674